Adhesive vinyl and Printable Vinyl have several benefits, the most important of which is the freedom to design and create your own designs. Self-adhesive vinyl is separated from the peel and self-adhesive backing of traditional paper substrates. This makes it a much more useful medium for graphic designers as they can get their design up and running without any hassle. High-resolution, self-adhesive vinyl forms a strong bond with the graphic while remaining flexible. It can withstand sub-zero temperatures without losing its adhesive properties, allowing it to be used in applications that come into contact with cold surfaces, such as sign, label, sign and display printing.

What is Adhesive Vinyl?

Self-adhesive vinyl is a high-quality, inexpensive, quick-to-assemble substrate that can be printed on. It is a flexible and flexible polymer that can be applied to various substrates such as paper, canvas, metal, and glass.

How to use self-adhesive vinyl and sublimation paper

One of the first things to consider when designing a project with self-adhesive vinyl is the type of paper to use. If you use plain paper, you can cut it to size or glue it to cardboard. If you are using special paper, we recommend ordering it in advance as it will only print on one copy and is used only for the sheet.

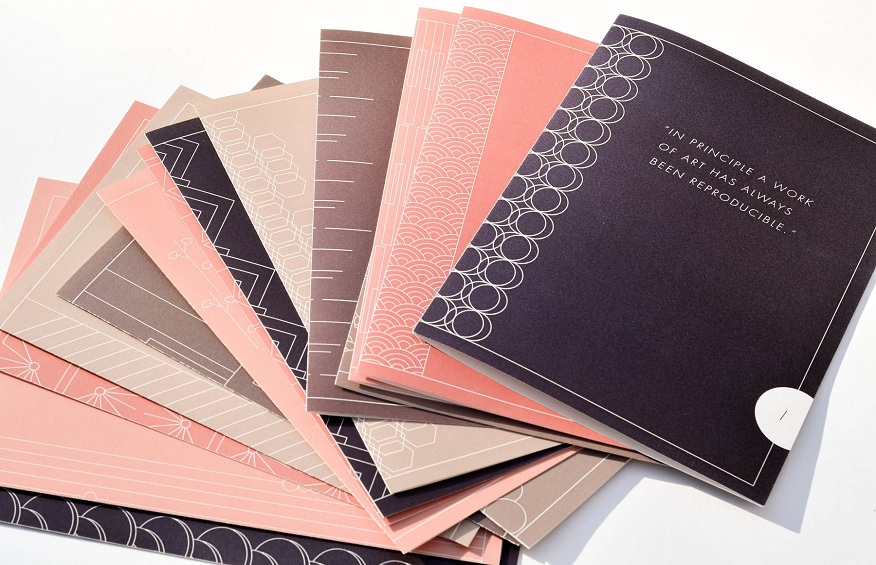

Types of adhesive vinyl

There are several types of self-adhesive vinyl, each with its own characteristics. Here are some of the most common adhesives. Water-Based Adhesives – Water-based adhesives can be used on a variety of substrates, including water-soluble papers and plastics. They are often used for signage or printed shrink dings. Oil-based adhesives – Oil-based adhesives are used on non-aqueous substrates and can provide a glossy finish or sandwich quality structure. It is often used in design projects where strong visual impact is important, such as banners, signs, and printed materials. Water-Resistant Adhesives – Water-resistant adhesives are formulated to bond to both water- and oil-based substrates providing resistance to rain and water droplets, snow and ice, sand and seawater. It is often used for printing shrink dings, but can also be used on water-based media.

Why choose self-adhesive vinyl?

Adhesion – Self-adhesive vinyl and sublimation paper are very “sticky” to each other, so the adhesion is stronger when printed on one sheet of paper than when printed on two separate sheets.

This is especially useful when you want to create a powerful visual impact with just a few designs.

Reusability – Self-adhesive vinyl and sublimation paper are versatile and easily recyclable, making them great partners for creating affordable, high-quality prints and graphics.

Drying time – When printing on dry paper, the speed with which you press the substrate determines how “curled” the paper is. Drying time is the time it takes for a printed sheet to fully cure after exposure to air. Paper usually feels hard or crunchy the moment you open it, but it takes a while for the ink to dry. Drying time is usually 30-60 seconds.