Recurring tasks not only diminish workforce engagement but also have detrimental effects on a company’s efficiency and financial performance. Surveys reveal that over 40% of employees across diverse industries allocate at least a quarter of their workweek to manual, repetitive duties. In the manufacturing sector, these routine responsibilities often encompass data gathering and manual data input. Many individuals opine that these obligations represent an inefficient use of employees’ time, considering the extraordinary automation capabilities currently at our disposal.

Beyond automation, there are alternative approaches to curbing manual and repetitive tasks. Numerous manufacturing firms are integrating cutting-edge robotic technology. These pre-programmed robots, also referred to as robot-controlled machines, leverage artificial intelligence (AI) to enhance an organization’s capabilities in processing, material handling, and assembly. When deployed in a controlled environment, robots can undertake physically demanding or monotonous tasks that might otherwise pose risks to employees, either in terms of injury or morale. Consequently, this leads to a notable reduction in labor costs and a substantial boost in productivity.

Outlined below are several instances illustrating how organizations are harnessing technology to mitigate, or even eradicate, repetitive tasks within the manufacturing industry.

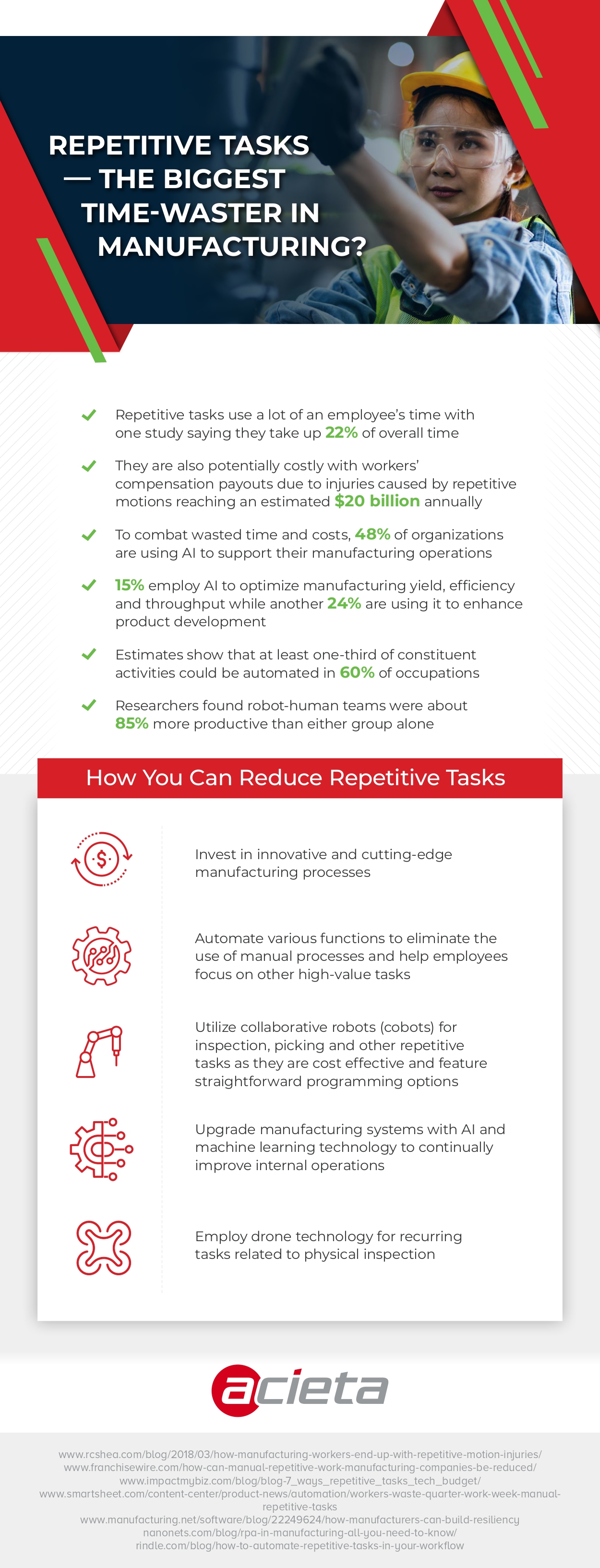

Repetitive Tasks in Manufacturing from Acieta, a manufacturing robotic company